How Is Racetrack Grip Maintained?

Racetrack grip is maintained through a combination of engineered surface design, continuous maintenance, real-time data analysis, and controlled tyre-surface interaction. In Formula 1, grip is the physical friction force between the tyre and the track surface. It allows a car to accelerate, decelerate, and corner at speed. Without sufficient grip, a car cannot follow the intended racing line, stop safely, or deliver lap time consistency. The entire performance envelope of a Formula 1 car depends on maintaining optimal grip throughout each lap, under varying loads and conditions.

Grip is essential for outright speed, and it also underpins safety, tyre management, and strategic flexibility. Every braking zone, apex, and acceleration point on the circuit relies on grip to hold the car on track. Without it, even the most advanced machinery becomes unstable. This makes grip management one of the most critical and least forgiving elements in race preparation and circuit design.

Several key factors influence racetrack grip, including:

- The composition and texture of the asphalt

- The temperature and cleanliness of the surface

- The type and condition of tyres used

- The presence or absence of rubber build-up from previous sessions

- External conditions such as rain, wind, and debris

- Real-time variables like weight transfer, downforce, and tyre temperature

To maintain consistent grip, circuits undergo regular cleaning, resurfacing, and surface monitoring. Engineers and FIA inspectors measure surface roughness, drainage performance, and grip coefficients. During race weekends, teams adapt their setups based on telemetry that tracks grip variation lap by lap.

This article breaks down exactly how racetrack grip is created, how it evolves, and how teams and track managers work to preserve it…

What Determines Track Grip?

Track grip in Formula 1 is never static. It is shaped by the interaction between tyres and asphalt, influenced by surface roughness, temperature, rubber deposits, and atmospheric conditions. These variables define how well a car can accelerate, brake, and corner.

Drivers who read the track accurately and manage grip effectively are more likely to control tyre degradation, optimise strategy, and secure a competitive advantage.

The Science Behind Tyre-to-Asphalt Interaction

Formula 1 grip begins with the fundamental relationship between the tyre and the track surface. The contact patch, though small in size, must provide enough traction to manage acceleration, braking, and cornering forces. Grip emerges from the tyre’s viscoelastic deformation, which allows it to conform to the microscopic features of the track surface. This mechanical interlocking forms the base layer of traction.

The tyre’s compound also plays a crucial role. Softer compounds provide higher levels of grip but degrade quickly, while harder compounds are more durable but offer less traction. Engineers use data to model grip profiles for each compound based on track characteristics and weather conditions. These profiles help teams decide which tyres will perform best at different stages of a race.

Downforce increases the vertical load on the tyres without adding mass, which amplifies the contact force and improves grip. This is especially critical at high speeds, where aerodynamic load exceeds the car’s weight. The balance between mechanical and aerodynamic grip is fine-tuned in setup sessions, with continuous adjustments made based on evolving conditions.

Ultimately, maintaining optimal grip requires a harmonised approach involving tyre chemistry, suspension tuning, and aero configuration. Every F1 team devotes significant resources to refining this triad, as it directly influences performance, tyre wear, and strategic options.

How Surface Roughness and Temperature Affect Grip

Track surfaces are designed with specific roughness profiles that enhance mechanical grip. Engineers assess both macro-roughness (spacing between surface aggregates) and micro-roughness (texture of individual stones) to determine how tyres will interact with the surface. A higher macro-roughness provides more physical anchoring for tyres, while micro-roughness boosts molecular bonding through adhesion.

Temperature is another crucial factor. Warmer surfaces soften the tyre compound, allowing for better conformity and grip. However, excessively high temperatures can push tyres beyond their optimal operating window, leading to degradation such as blistering or graining. Conversely, colder conditions make rubber less pliable, limiting adhesion and increasing the risk of sliding.

Track colour and surface age also influence thermal properties. Darker, newer asphalt heats quickly under sunlight, which can accelerate rubber laydown but also challenge teams to manage overheating. Engineers use infrared sensors and thermal imaging to monitor surface temperature in real time and adjust tyre pressure and compound selection accordingly.

Surface contaminants such as oil, fuel residue, or dust reduce available grip. Even small irregularities can cause a significant loss of traction. This is why track cleaning and maintenance routines are vital not just for safety, but for ensuring consistent performance across a race weekend.

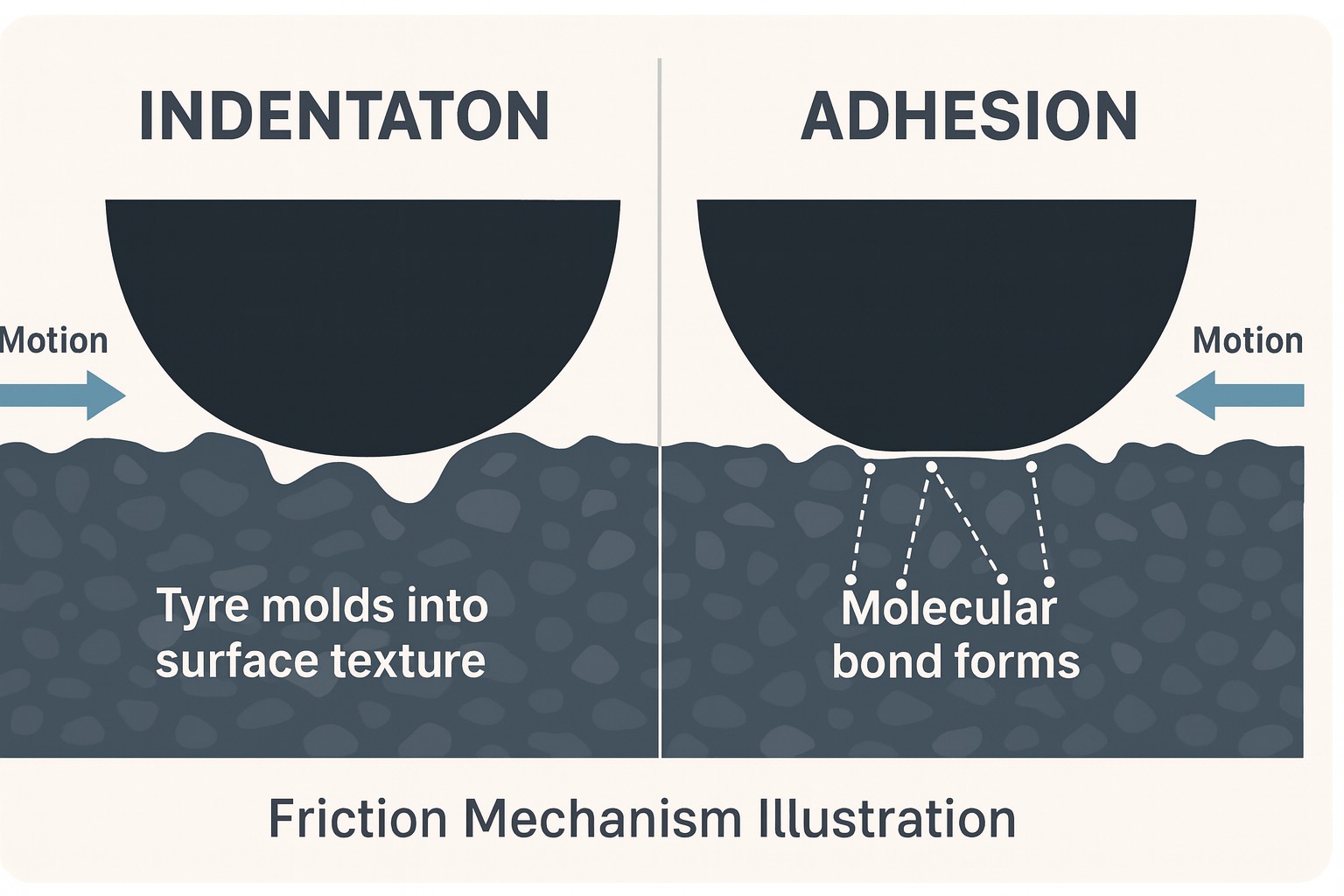

Adhesion and Indentation: The Physics of Friction

Tyre grip arises from two complementary mechanisms: indentation and adhesion. Indentation refers to the tyre’s ability to deform around the track’s roughness, generating friction through mechanical resistance. Adhesion is the molecular bonding that occurs between rubber polymers and the surface at a microscopic level.

These two forces operate simultaneously. On a clean, high-roughness surface, indentation is the dominant contributor to grip. On smoother tracks or in wet conditions, adhesion becomes more critical. Tyres are engineered to balance both effects through compound formulation and tread design in the case of wet tyres.

Grip levels are dynamic, influenced by load transfer, surface temperature, and speed. For example, during braking or cornering, vertical and lateral loads shift the contact patch, altering the distribution of adhesion and indentation forces. This dynamic grip envelope is modelled using telemetry data to fine-tune setup and race strategy.

Understanding the balance between these forces allows teams to adjust parameters such as camber, toe angle, and tyre pressure to maximise friction. This directly affects lap times, tyre life, and the car’s ability to defend or attack during critical race moments.

Track Evolution and the Impact of Rubber Build-Up

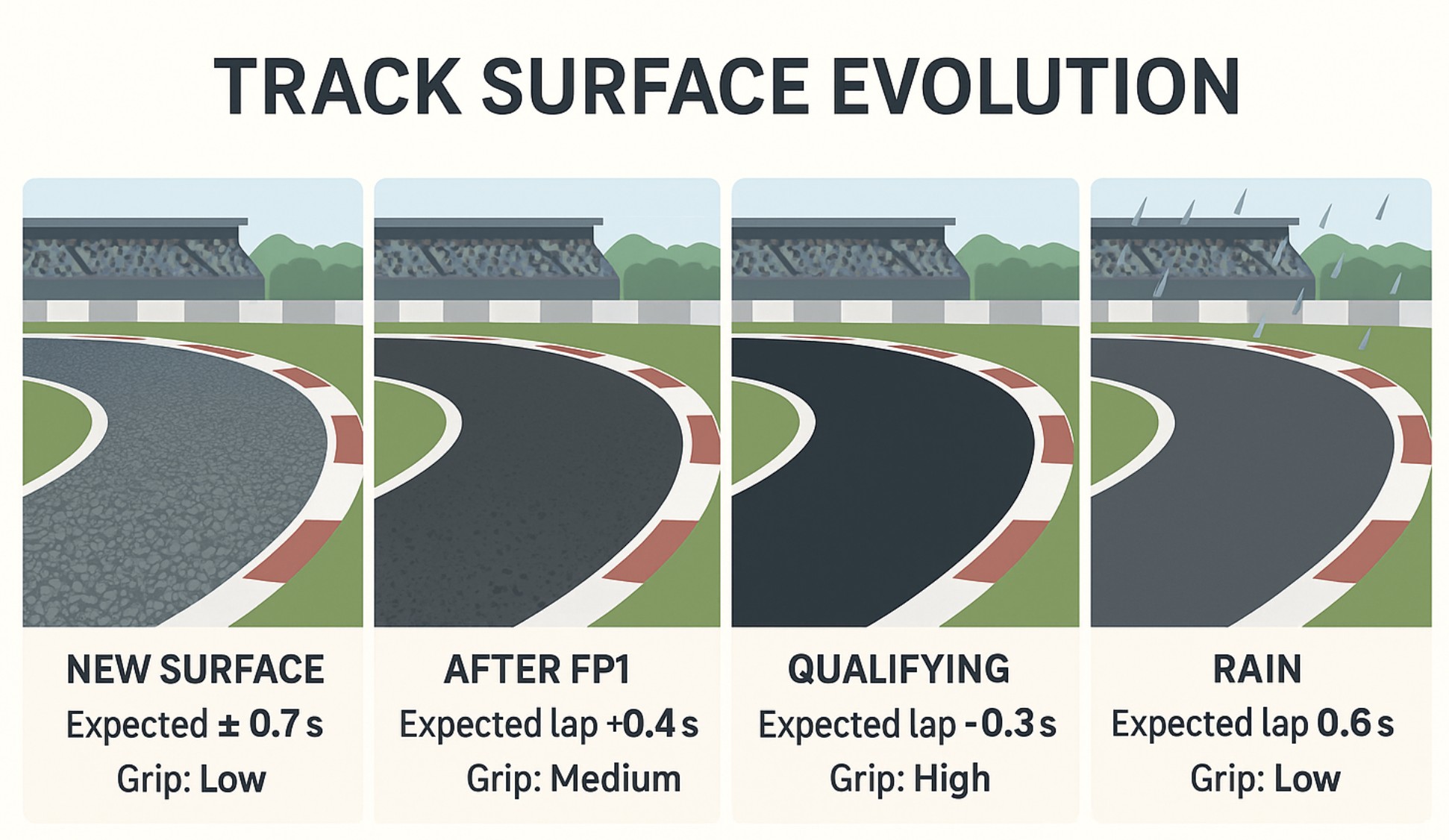

As Formula 1 cars circulate, tyres shed small amounts of rubber onto the track surface, particularly on the racing line. This process, known as track evolution, increases grip session by session. The deposited rubber fills in surface voids, reducing macro-roughness and enhancing both adhesion and indentation.

Track evolution is most pronounced during dry race weekends. The early sessions on a “green” track tend to be slower, but lap times improve as rubber builds up. However, this progression can be reset by rain, which washes rubber away and reintroduces surface contaminants. Teams must adapt to these changes with real-time data analysis and flexible strategies.

The rate of evolution varies by circuit type and surface composition. Permanent racing circuits with high-resin asphalt see faster rubber retention, while temporary street circuits require more time to develop usable grip due to smoother surfaces and pre-race contaminants. Some tracks, like Monaco or Singapore, may even require rubbering-in overnight to maintain consistent grip levels.

Tyre engineers monitor grip build-up using surface temperature sensors, onboard cameras, and satellite telemetry. This information feeds into live strategy models that help teams decide when to push, when to switch compounds, and how to manage stint lengths for optimal performance.

Types of Grip in Formula 1

Grip in Formula 1 is a multi-dimensional concept. It is not a single value, but rather a balance of forces generated through tyre contact, aerodynamic load, surface temperature, and power delivery. Each type of grip influences how the car behaves under braking, acceleration, and cornering. Engineers and drivers work together to maximise each grip category, while maintaining balance across the car. Mismanaging one type of grip can compromise another, so all must be considered as part of a unified system.

Mechanical Grip: Tyre Load and Suspension Geometry

Mechanical grip originates from the physical connection between the tyres and the track. It is governed by the vertical load applied to the tyre and the ability of the suspension to manage that load across varying surface conditions. Unlike aerodynamic grip, which increases with speed, mechanical grip is always present and becomes more dominant at lower speeds.

The load on each tyre changes constantly based on weight distribution and track gradient. Engineers manipulate spring rates, damper settings, and anti-roll bars to optimise the distribution of this load. Suspension geometry, such as camber, toe, and caster, directly affects the tyre’s contact patch and how consistently it maintains surface contact during dynamic phases like braking or cornering.

Key mechanical grip factors include:

- Tyre compound and construction

- Contact patch size and deformation characteristics

- Suspension travel and roll stiffness

- Anti-dive and anti-squat geometry

In slow-speed corners or on tracks with limited downforce zones, mechanical grip becomes the primary means of keeping the car on the racing line. This is why ride height and suspension tuning are so critical in street circuits, where surface variation is high and aerodynamic forces are limited.

Aerodynamic Grip: Downforce and Contact Pressure

Aerodynamic grip is generated by the downward force applied to the car as airflow passes over the wings, floor, and diffuser. This downforce increases the vertical load on the tyres without adding weight, allowing the tyres to produce more friction without exceeding structural limits. The faster the car moves, the more aerodynamic grip it generates.

The front and rear wings, underbody tunnels, and beam wings are shaped to manage both downforce and drag. The floor of the car, regulated heavily under current ground-effect rules, contributes significantly to aerodynamic load. Venturi tunnels under the floor accelerate airflow and lower pressure, effectively pulling the car towards the ground.

Aerodynamic grip considerations include:

- Ride height sensitivity to maintain optimal ground clearance

- Flow conditioning devices such as bargeboards and vortex generators

- Brake duct design to balance cooling and airflow stability

- Rear wing angle and DRS activation zones

Aerodynamic grip enables high-speed cornering but is susceptible to turbulence. Dirty air from leading cars can disturb airflow and reduce downforce. This is why following closely in corners remains a challenge, despite ongoing efforts to simplify aero wake effects under current technical regulations.

Thermal Grip: Operating Windows and Heat Cycles

Thermal grip refers to how tyre temperature affects available friction. Tyres must operate within a narrow temperature window to generate optimal grip. If they are too cold, the rubber is stiff and cannot conform to surface textures. If overheated, oils in the rubber compound can migrate to the surface and reduce traction.

F1 teams use tyre blankets to preheat tyres before installation. Once on track, braking, cornering, and acceleration contribute to surface and core temperature changes. Drivers must bring tyres into the operating range quickly, but without overloading them. Maintaining that range throughout a stint is a critical factor in race strategy.

Thermal grip is influenced by:

- Track surface temperature and ambient conditions

- Tyre compound softness or hardness

- Brake balance and heat transfer into the wheel assembly

- Driving style, including throttle modulation and steering input

Managing thermal grip is particularly difficult during safety car periods or in wet conditions, where tyre temperatures fall rapidly. Losing thermal grip often precedes a sudden loss in overall performance, forcing unscheduled pit stops or defensive driving to avoid off-track incidents.

Traction Management: Throttle Control and Power Delivery

Traction is a specific form of grip that relates to how well the rear tyres convert engine torque into forward motion. This is especially important when exiting corners, where throttle application must be carefully managed to avoid wheelspin. Excessive slip leads to energy loss, tyre wear, and possible loss of control.

Power delivery in F1 is highly sophisticated. Torque maps, differential settings, and hybrid deployment curves are all tuned to match traction demand at each corner. The interaction between the internal combustion engine and the electric motor also affects how smoothly power is applied to the rear axle.

Key traction management systems include:

- Throttle mapping by corner type and surface grip

- Torque split control via the limited-slip differential

- Engine braking calibration during lift-off phases

- ERS (Energy Recovery System) deployment synchronised with traction zones

In low-grip conditions such as wet races or after a safety car restart, traction control becomes the driver’s responsibility. They must judge available grip based on feel, feedback, and telemetry, modulating throttle with millimetre-level precision to maintain acceleration without destabilising the car.

Combined Grip: Managing Lateral and Longitudinal Forces

Grip is never used in isolation. Braking, turning, and accelerating all draw from the same grip reserve. The challenge is to blend lateral (cornering) and longitudinal (braking or accelerating) forces within the tyre’s limits. Exceeding this total friction budget leads to slides, lock-ups, or wheelspin.

The traction circle is a conceptual model used to illustrate how grip is shared. A driver at full braking capacity cannot steer aggressively without releasing some braking force. Likewise, exiting a corner while still turning requires gradual throttle application to avoid exceeding lateral grip.

Combined grip demands:

- Smooth transitions between braking and turning phases

- Effective use of trail braking to manage weight transfer

- Early steering correction to balance entry and exit grip

- Real-time data interpretation to adjust driving technique on the fly

Understanding combined grip is what separates elite drivers from the rest. They can extract the maximum possible grip at every stage of a corner without crossing the threshold. Car setup plays a role, but ultimate grip exploitation is a function of skill, consistency, and feedback response.

Engineering the Track Surface

The construction and maintenance of a racetrack surface are fundamental to the grip levels Formula 1 teams experience across a race weekend. While tyres, aerodynamics, and weather conditions all play a role in grip generation, none of it works as intended without a properly engineered racing surface. Unlike conventional roadways, an F1 track must withstand extreme forces, provide consistent grip under varying temperatures, and offer predictable surface behaviour across hundreds of laps. This level of performance requires specialist materials, unique laying techniques, and continuous monitoring for degradation.

What Makes F1 Asphalt Different from Road Materials?

Formula 1 tracks are not built using standard road asphalt. Instead, they use high-performance mixes specifically engineered for grip, load tolerance, and thermal behaviour. The primary component is still bitumen-bound aggregate, but both the binder and the stone selection are highly customised. Stone Mastic Asphalt (SMA) is the most common method, offering a dense, interlocking structure that resists deformation under load while maintaining consistent surface texture.

The choice of aggregate has a direct influence on both micro and macro roughness. Some F1 circuits import specific types of granite or basalt from quarries known to provide stones with high grip potential and minimal polish rate. This helps maintain roughness throughout a season and delays the onset of surface wear. The asphalt composition is also temperature-calibrated to match the local climate, ensuring that the binder does not soften excessively in heat or become brittle in cooler conditions.

Key differences in F1-grade asphalt:

- Higher aggregate content and stone-on-stone structure for load stability

- Specialised bitumen binders with enhanced elasticity and ageing resistance

- Controlled surface porosity to prevent water pooling and support wet-weather grip

- Precision laying techniques to reduce seams and irregularities across the racing line

The entire laying process is controlled down to the millimetre, with surface levelling, laser-guided compaction, and texture analysis performed during and after installation. This guarantees uniform grip, particularly through high-speed corners and braking zones where traction variability can compromise both safety and performance.

Bitumen Bleeding and Surface Contamination Risks

Even the best-laid surfaces can become compromised if subjected to improper usage or environmental stress. One of the most significant risks to grip is bitumen bleeding. This occurs when the bitumen binder softens under high track temperatures and begins to migrate to the surface, forming a smooth, oily film. This greatly reduces the available friction, particularly in braking zones and corner exits.

Bitumen bleed is more likely on newly resurfaced tracks or during hot weather events. Circuits with dark aggregate compositions absorb more solar energy and are at higher risk. Once bleeding begins, tyre rubber cannot adhere properly, and the result is a marked increase in lock-ups, wheelspin, and off-track excursions. It can also lead to irregular tyre degradation and reduced thermal grip.

Other sources of surface contamination include:

- Fuel and oil deposits from support categories with less regulated powertrains

- Rubber marbles from previous sessions, which accumulate off the racing line

- Dust and sand intrusion at desert-based circuits like Bahrain or Qatar

- Water infiltration due to poor drainage or high humidity

Track marshals and circuit managers must be vigilant in cleaning, sweeping, and inspecting the track before each F1 session. In some cases, abrasive brushing or chemical treatment is required to restore surface texture.

Optimising Temporary Circuits for Consistent Grip

Temporary circuits present a unique engineering challenge. Street tracks and non-permanent layouts often incorporate a mix of asphalt, concrete, painted lines, and road markings. These surfaces were never designed for racing and usually have vastly different grip levels across a single lap. Formula 1 organisers and circuit engineers must intervene to standardise grip without permanently altering public roads.

One method involves selective resurfacing of high-load zones such as braking areas and apexes. These sections are stripped and relaid using F1-grade asphalt while the rest of the track remains untouched. In some cases, special coatings are applied to improve surface adhesion or reduce the slipperiness of painted kerbs and crosswalks. Temporary circuits also employ aggressive cleaning regimes, often using high-pressure water and industrial sweepers to remove urban contaminants such as oil, brake dust, and debris.

Temporary grip enhancements include:

- Polymer-based asphalt sealants to increase surface cohesion

- High-friction epoxy treatments on low-grip concrete sections

- Installation of temporary kerbs with engineered texture profiles

- GPS-based measurement of track evolution to guide weekend setup

Another consideration is the tyre warm-up phase. At temporary venues, track evolution is rapid and unpredictable, with grip levels changing significantly between sessions. Teams often request additional track time or make aggressive setup adjustments to cope with the lack of baseline data. The absence of rubber laid down in the days before the event can also lead to a “green” track that punishes early push laps and limits strategic flexibility.

Effective temporary track engineering must balance urban infrastructure constraints with Formula 1’s performance demands. When managed well, it can create thrilling races and high levels of challenge. When neglected, it leads to chaos, safety issues, and widespread tyre complaints.

Real-World F1 Track Maintenance Procedures

Maintaining grip on a Formula 1 circuit does not end once the asphalt is laid. In fact, that is only the beginning. Every race weekend places enormous mechanical, thermal, and chemical stresses on the surface, which must be managed with a rigorous set of maintenance protocols. Track operators and the FIA collaborate to ensure that circuits deliver consistent grip from Free Practice through to the chequered flag. The maintenance process involves daily inspections, active cleaning, drainage management, and structural interventions that go far beyond the racing line.

Daily Cleaning and Marbles Removal

During every race weekend, circuits accumulate rubber debris known as marbles. These are small chunks of tyre compound sheared off during acceleration, braking, and cornering. Marbles collect outside the racing line and can create extremely low-grip areas that punish even minor driver errors. If left unchecked, they can make overtaking dangerous and increase the likelihood of spins when a driver is forced wide.

Track crews are tasked with cleaning marbles after each session using industrial sweepers equipped with rotary brushes and vacuum suction systems. In some cases, a water-based rinse follows to lift any remaining particles embedded in the surface texture. This process is done between sessions to avoid altering the rubber laid down on the racing line. FIA technical delegates monitor the condition of the track and request additional cleaning if grip levels begin to degrade.

Daily surface cleaning also includes:

- Removal of oil and fuel spills from support categories

- Clearing of dirt or debris introduced by wind or trackside activity

- Reapplication of anti-slip coating on high-wear kerbs

- Inspection of painted zones for peeling or contamination

These tasks are often performed during the overnight window or in the early morning before cars return to the circuit. Even a delay in this schedule can have a measurable impact on grip in opening laps of practice or qualifying.

Managing Drainage to Prevent Surface Degradation

Water is one of the most destructive forces a racetrack surface can face. Poor drainage leads to standing water, which not only creates aquaplaning hazards but also degrades the binder that holds the aggregate together. This weakens the asphalt and leads to premature cracking, potholes, or surface breakup under load.

To prevent this, modern circuits are constructed with an integrated drainage system that includes crown profiles, grooved surfaces, and subsurface piping. The track is built with a subtle camber that directs water away from the racing line towards strategically placed drainage channels. These are located on both sides of the track and often hidden beneath kerbs or run-off zones. In areas prone to heavy rain, such as Suzuka or Spa-Francorchamps, drainage capacity is scaled to manage sudden downpours without compromising grip.

Drainage maintenance involves:

- Regular flushing of subsurface drains to prevent sediment buildup

- Camera inspections to detect blockages or root intrusion

- Surface integrity checks near manholes and grates

- Replacement of cracked drain covers or loose fitting grids

Failure to maintain these systems can cause water pooling, which accelerates surface ageing and introduces unpredictable grip levels. In some cases, water can even seep up from below if the sub-base becomes saturated, causing patchy grip loss known as “weeping.”

When and Why F1 Circuits Are Resurfaced

Despite regular maintenance, every circuit surface has a limited lifespan. Most F1-grade asphalt requires resurfacing every seven to twelve years depending on the climate, event schedule, and material composition. High-degradation circuits or those with harsh winters tend to require more frequent interventions. Resurfacing is typically scheduled in the off-season to allow for proper curing, testing, and homologation.

Resurfacing is usually triggered by one or more of the following:

- Consistent complaints from drivers about grip loss or tyre damage

- Evidence of surface delamination, potholes, or aggregate polishing

- Introduction of new tyre compounds or regulations requiring higher loads

- Strategic desire to alter corner behaviour or improve overtaking potential

The resurfacing process involves milling off the top layer of asphalt, recalibrating the base, and relaying a new surface using a custom mix. Special attention is given to the racing line, where compound behaviour is most sensitive. After laying, the track is tested using grip measurement devices and simulation tools to ensure it meets FIA specifications. Only after this process is complete will the circuit be reapproved for competition.

New surfaces often require a bedding-in period. As seen at Istanbul Park in 2020, freshly laid asphalt can have excessively low grip due to a sealing layer of bitumen. Organisers now schedule non-F1 running before race weekends to accelerate rubbering-in and restore usable traction.

Maintenance Beyond the Racing Line: Kerbs, Paint, and Safety Zones

Grip maintenance extends well beyond the black tarmac strip of the racing line. Kerbs, painted surfaces, and run-off areas all affect how a car behaves under load, especially during wheel-to-wheel racing. If these zones offer inconsistent grip, drivers are more likely to lose control or be unable to recover from a small error.

Kerbs are maintained for shape, paint adhesion, and surface texture. Painted kerbs become slippery when worn or wet, so some tracks use rough enamel coatings or embedded aggregate to retain grip. Their height and bevel are also critical, as modern F1 cars can bottom out or lose floor performance when launched over sharp edges.

Painted zones and start grids are subject to:

- Anti-slip coating to maintain grip in wet conditions

- Colour retouching to preserve visual cues and FIA visibility standards

- Adhesion testing to prevent flaking or chemical leaching

Run-off areas, whether asphalt or gravel, must be checked for compaction, drainage, and obstacle clearance. Tarmac run-offs require the same maintenance as the main track, while gravel beds are raked and inspected for uniformity and depth. Tyre barriers, Tecpro units, and catch fencing are also reviewed to ensure impact energy is absorbed correctly.

These outer zones serve as the final line of grip recovery. Their upkeep is not aesthetic, but a direct contributor to both race safety and vehicle control under non-ideal conditions.

FIA Standards and F1 Circuit Certification

Before a track can host a Formula 1 Grand Prix, it must meet stringent safety, performance, and surface requirements set out by the FIA. Grip is a core consideration in the certification process, as it directly affects vehicle control, accident prevention, and the consistency of competitive conditions. Circuits aiming to host F1 races must obtain and retain a Grade 1 licence, which demands detailed testing and ongoing compliance across a range of technical parameters. These standards are not static. They are periodically reviewed and updated in line with evolving car performance, surface technologies, and safety protocols.

Beyond layout and barrier placement, the surface composition, grip coefficient, and water dispersion capability are essential to the approval process. A circuit can fail inspection if any of these factors fall outside the defined tolerances, regardless of its heritage or financial value to the sport. As the performance envelope of modern F1 machinery increases, so too do the expectations for the track’s ability to deliver predictable and uniform grip in all zones.

FIA Grade 1 Grip Testing and Measurement Tools

To assess whether a circuit meets the required grip levels, the FIA uses several tools and methodologies. One key instrument is the Surface Friction Tester (SFT), which measures the coefficient of friction across various parts of the track. This device is often mounted to a trailer towed behind a vehicle and can simulate wet conditions using controlled water dispersion to test for both dry and wet grip characteristics.

Other technologies include laser-based surface profilers that map micro and macro roughness over large surface areas. These measurements are used to model how tyres will interact with the track under load. Inspectors also monitor surface uniformity to identify inconsistencies in grip that may pose risks to drivers. These values are recorded before every major resurfacing, and again during recertification procedures, to benchmark improvements or detect regression.

Data is collected from high- and low-speed corners, braking zones, and start-finish straights. Any area with a variance in grip coefficient outside of the accepted range may trigger resurfacing or require remedial surface work before a licence is renewed.

Cost, Frequency, and Requirements of Track Recertification

Track recertification is not a one-off process. FIA Grade 1 certification is typically valid for three years, after which a full reassessment is required. Even during the certification period, interim inspections may be triggered by complaints, incidents, or environmental changes. For example, unexpected surface wear after a heatwave or changes in asphalt composition during minor repairs can initiate a spot review.

Recertification is a costly and resource-intensive process. Most venues allocate several million dollars annually for compliance-related maintenance. These costs cover resurfacing, inspection fees, tooling upgrades, and test runs using FIA-authorised equipment. Host circuits must demonstrate ongoing investment in safety infrastructure and surface performance to retain Grade 1 status.

Some venues, such as Silverstone and Spa-Francorchamps, have undergone multiple resurfacing projects within a decade due to failures detected during FIA grip audits. In other cases, resurfacing is done preemptively based on predictive wear models and FIA advisory thresholds to avoid last-minute race jeopardy.

How FIA Inspections Influence Track Design and Resurfacing

FIA inspections extend beyond pass-or-fail metrics. The audit process often influences future track upgrades, design changes, and surface selection. For example, if a corner consistently shows low grip or poor drainage, designers may adjust the camber, modify surface composition, or revise run-off geometry in response to FIA feedback.

When a section of track is resurfaced, it must be retested for friction, uniformity, and water evacuation. This ensures that piecemeal updates do not compromise the broader grip profile of the circuit. The FIA has also introduced stricter tolerances on surface transitions between old and new asphalt, which were once responsible for unpredictable tyre behaviour during braking and corner entry.

Track designers and civil engineers now work closely with FIA officials during resurfacing planning. In some cases, test rigs and simulation data are submitted months in advance to pre-clear asphalt mixes or construction methodologies. This collaborative process reduces delays and ensures consistency across global circuits operating under Grade 1 standards.

Core F1 Circuit Maintenance Principles for Long-Term Grip

Maintaining grip at a race-ready level requires more than resurfacing or sweeping between sessions. Circuit longevity and grip consistency rely on a foundation of engineering discipline, surface science, and predictive monitoring. Each element, from the aggregate mix to the way rubber residue is handled between events, contributes to whether a track continues to deliver stable and measurable friction characteristics over time. This long-term view of track maintenance aligns with the requirements of modern Formula 1, where marginal differences in grip can alter race outcomes, safety margins, and even championship trajectories.

Asphalt Mix and Aggregate Composition Standards

Grip begins with the foundational composition of the racetrack surface. Most Formula 1 circuits use a blend of stone mastic asphalt or polymer-modified asphalt designed specifically for high load-bearing capacity, drainage, and grip retention. The exact ratio of bitumen binder to aggregate, and the choice of stone type, directly affect macro and micro roughness, as well as temperature responsiveness.

The aggregate must remain stable under the shearing forces generated by F1 tyres and consistent across sections of track. Stone origin is often controlled, with many circuits importing specific grades of aggregate from trusted quarries to maintain friction performance and surface resilience. Over time, surface polishing of the stone due to tyre wear or weather exposure can reduce grip, which is why inspections must track aggregate texture loss over seasons.

Reapplication of surface coatings or slurry seals can restore grip between full resurfacing projects. However, these treatments must be carefully matched to the original asphalt specification to prevent sudden transitions in grip levels, especially during braking and turning phases.

Rubber Management Between Sessions and Events

One of the most significant variables in long-term grip maintenance is rubber accumulation. Tyres deposit microscopic and macroscopic rubber layers throughout race weekends. In high-friction areas, this creates a progressive grip improvement known as track evolution. But outside of racing lines, excess rubber can create loose debris known as marbles, which reduce grip and cause instability.

Between sessions, tracks are swept to remove these deposits, often using rotating brushes, compressed air systems, or vacuum trucks. The timing and intensity of these clean-ups are carefully managed to preserve useful rubber buildup on the racing line while clearing hazards elsewhere. A surface that is too clean can revert to a lower grip baseline, particularly if it has been recently resurfaced or lacks natural porosity.

For circuits that host multiple categories, like GT or junior formulae, the type of rubber laid down can affect the performance of F1 compounds. Managing this cross-contamination is part of the operational plan for multi-series weekends and plays a role in how grip levels fluctuate between sessions and days.

Temperature, Drainage, and Their Role in Year-Round Grip

Track temperature is a central variable in how tyres generate grip, but the ability of the surface to handle thermal changes and water dispersion throughout the year is just as important. Inconsistent heating or poor drainage can create isolated grip loss, hydroplaning, or accelerated surface wear.

High-performance circuits are engineered with subsurface drainage channels and crowned road geometry to disperse water efficiently. Surface porosity is also tuned to allow water to pass through or across without pooling. Areas with flat geometry or insufficient gradient are vulnerable to standing water, which can lift tyres off the surface entirely and destroy grip.

Temperature also plays a role in bitumen behaviour. In hot conditions, bitumen can rise to the surface and form a slick layer, reducing friction and creating unpredictable braking zones. This is especially problematic if the surface binder was not selected with heat stability in mind. Regular monitoring of surface temperature and bitumen viscosity helps pre-emptively manage these risks, often prompting short-term surface treatments before major events.

Why Regular Testing Is Essential for Race-Ready Surfaces

Without continuous testing, circuits cannot guarantee grip performance across the entire surface. Annual or seasonal inspection regimes are built into circuit maintenance plans to measure friction levels, drainage efficiency, and surface roughness. These inspections use a mix of static measurements and dynamic test runs using control vehicles fitted with calibrated sensors.

Surface friction levels are benchmarked using standardised devices such as the British Pendulum Tester or continuous friction measuring equipment (CFME) dragged behind test vehicles. These readings are then compared with FIA performance standards and historical data to detect grip loss or variation. If measurements fall below minimum values in critical areas, resurfacing or remedial works are initiated ahead of time.

Testing is particularly important after weather extremes, resurfacing, or heavy multi-category usage. It is also mandated before any track can be recertified or approved for race hosting under FIA Grade 1 standards. Tracks that perform regular testing and data logging are better able to predict maintenance cycles and avoid last-minute repairs or cancellations.

By combining strict surface engineering, real-time data analysis, and proactive maintenance, Formula 1 circuits can maintain grip performance across seasons and racing formats. The science of grip is not static. It is an ongoing responsibility that defines both the safety and spectacle of every Grand Prix.

This article was developed with technical analysis provided by Bet Carolina. For fans interested in racing, the Bet365 sportsbook North Carolina offers detailed odds and insights throughout the F1 season.

From F1 news to tech, history to opinions, F1 Chronicle has a free Substack. To deliver the stories you want straight to your inbox, click here.

For more F1 news and videos, follow us on Microsoft Start.

New to Formula 1? Check out our Glossary of F1 Terms, and our Beginners Guide to Formula 1 to fast-track your F1 knowledge.