The Science Behind F1 Tyres: How They Withstand Extreme Forces

It’s no secret that Formula One cars are built differently, but how hard are F1 tyres exactly? Ever since its historical first world championship race in 1950, Formula One has always been about engineering and technology.

Through the years, Formula 1 tyres have evolved and undergone changes over time. At first, several manufacturers provided tyres to Formula 1 teams. From Goodyear to Avon, they all had their fair share of Formula 1 fame through the years.

The first ten years saw Formula 1 cars equipped with tall, thin, tread tyres. During the 1960s, the tyres became flatter and also wider. The rear and front tyres were the same size back then. As the end of the decade approached, however, larger rear tyres started to take over.

Formula 1’s tyre technology took off with the debut of slick tyres in the 1970s. They first appeared at the Spanish Grand Prix in 1971. The playground was Goodyear’s turf during the mid-seventies thanks to their cross-ply slicks and it lasted until Michelin’s entrance to Formula 1 in 1977. This also kickstarted the downpour of tyre manufacturers to join the popular motorsport.

As new tyre manufacturers joined the fun, fierce competition also raged.

The first tyre blankets were used in 1985. The blankets are used while the car is on the grid and in the pits to warm up the tyres. In the absence of this prior heating process, the tyres would only last an average of two laps before they got their prime working temperature.

Grooved tyres entered the scene in 1998. Front tyres with 3 grooves and rear tyres with 4 grooves were the standard.

After all those years, however, Formula 1 decided to ban tyre changes during the race. This led manufacturers to make tyres out of harder compounds with the sole purpose of lasting a full race distance of around 200 km. this wasn’t received lightly by the masses and so, in 2006, tyre changes returned to the game.

Tyre manufacturers then left the sport one by one, with Pirelli becoming the only tyre company to supply all of the tyres in Formula 1 to this day.

Now that we have the brief history of Formula 1 tyres in place, let’s take a look at the technicalities that make these tyres that are basically the legs of the exhilarating motorsport.

Technical Aspects of F1 Tyres

Materials

F1 tyres are constructed from a complex mixture of natural and synthetic rubbers, reinforced with carbon fibre and Kevlar. The exact composition of the rubber compounds is a closely guarded secret, but it typically includes polymers, sulfur, carbon black, and other additives to optimize performance and durability. Pirelli, the official tyre supplier for Formula 1, carefully develops these compounds to meet the specific demands of F1 racing.

Manufacturing Process

The manufacturing process of F1 tyres involves several intricate steps. First, the rubber compounds are mixed to create the desired properties. Then, the mixed rubber is extruded into the shape of the tire and cured in moulds at high temperatures and pressures. After the tyres are moulded, they undergo rigorous quality control tests to ensure they meet the required specifications and are ready for the track.

Comparative Data

F1 tyres are specifically engineered for the unique demands of Formula 1 racing and are not directly comparable to tyres used in road cars or other motorsports. However, compared to tyres used in other forms of racing, such as endurance racing or rallying, F1 tyres are generally softer and offer more grip. They also operate at much higher temperatures, with surface temperatures often exceeding 100°C (212°F) during races, which is significantly higher than the operating temperatures of road car tyres.

How many types of F1 tyres are there?

Pirelli, the sole tyre supplier for Formula 1, supplies the teams with three compounds out of five slick compounds and three colours at each race. The range is numbered C1, C2, C3, C4 and C5. C1 is the hardest and C5 is the softest. The compounds are Pirelli’s solution to greater consistency during a full race. There are also two wet options: Cinturato Green intermediate and Cinturato Blue full wet tyres.

- C1 — the hardest tyres are designed for tracks that put the highest energy loadings through the tyres. Typically, these circuits have abrasive surfaces, fast corners or high temperatures. This type of tyre compound doesn’t warm up easily but is the most durable. It also gives low degradation.

- C2 — this compound fits high speeds, temperatures and energy loadings. Tyres of this make are best suited for a wide selection of circuits that are quite different to each other. It has a higher chance of adaptability and there’s a lot of room to work around.

- C3 — the middle of the range, this compound boasts adaptability. It can be equipped as the softest compound or hardest compound depending on the track. It is one of the most used compounds in Formula 1.

- C4 — this compound suits tight circuits that offer sharp twists and turns. Because it warm-ups rather quickly, it reaches its peak faster too. This has a downside, however, as softer tyres overheat quicker than the rest.

- C5 — the softest tyre in this range and also offers a huge boost in speed. This tyre is best used on circuits that require tighter mechanical grip. This, however, makes the tyre last shorter than the rest.

In addition to these five compounds, the wet compounds also have a use and benefit of their own on wet tracks.

- The intermediate tyres are deemed the most versatile. They work well on tracks that have no standing water and also a drying surface. At 300km/h, this tyre evacuates 30 litres of water every second.

- The full-wet tyres are much better options during heavy rain. When raining heavily, visibility becomes a problem rather than grip. These tyres have the ability to evacuate 85 litres of water per second per tyre at 300 kph. These tyres are also designed to resist aquaplaning quite well, allowing more grip during a heavy downpour.

How are F1 Tires Tested Before a Race?

Before an F1 race weekend, Pirelli conducts extensive testing to ensure that the tires are suitable for the specific circuit and conditions. This testing process involves both laboratory tests and on-track testing.

Laboratory testing is a crucial aspect of tyre development. Pirelli uses advanced machinery to simulate the forces and stresses that tyres experience on the track. Mario Isola, Head of Motorsport at Pirelli explained, “We have a lot of indoor testing, so we have our machines that are able to reproduce the forces and the stress on the tyre in a lab. And this is giving us a good idea of the level of integrity of the tyres.

In addition to laboratory tests, Pirelli also conducts on-track testing. This involves specially organised test sessions where teams run cars fitted with prototype tyres. These tests allow Pirelli to gather real-world data on tyre performance and durability. Isola stated, “We have a lot of data coming from telemetry, from the teams, and from our engineers. We analyze this data, and we use it to develop the tyres and to understand how to improve the tyres.”

During these on-track tests, teams provide valuable feedback to Pirelli. Isola mentioned, “The teams are providing us feedback, and they are also pushing us to develop new tyres, to improve the characteristics of the tyres.” This feedback, combined with the data collected by Pirelli’s engineers, helps the company refine the tyre compounds and structures to better suit the needs of F1 teams and drivers.

Furthermore, Pirelli also analyses data from previous races and tests to continually improve their tyres. According to Isola, “After each race, we analyze the data, we look at the tyres, we look at the wear profile, we look at the footprint, and we try to understand if there is any possibility to improve the product.”

This combination of laboratory testing, on-track testing, team feedback, and data analysis allows Pirelli to develop and refine F1 tyres that can withstand the extreme demands of Formula 1 racing while providing the performance characteristics needed by the teams and drivers.

How Soft Are F1 Tyres?

F1 tyres are significantly softer than regular road car tyres, as they are designed to provide maximum grip and performance on the track.

The softness of a tyre is determined by its durometer rating, which measures the hardness of the rubber. A lower durometer rating indicates a softer tyre, while a higher rating indicates a harder tyre. F1 tyres typically have a durometer rating between 50 and 60 on the Shore A scale, compared to road car tyres, which have ratings between 60 and 70.

To put this into perspective, a typical F1 tyre has a contact patch (the area of the tyre that touches the ground) of around 100 square inches (645 square centimetres), and can generate up to 5 g of lateral force during cornering. This is achieved through the use of soft, sticky rubber compounds that provide exceptional grip, but also wear out quickly.

The softness of F1 tyres also contributes to their ability to generate high temperatures. During a race, tyre surface temperatures can reach up to 212°F (100°C), which helps to further improve grip. However, this also means that the tyres have a limited lifespan and must be managed carefully throughout a race stint.

According to Pirelli, the softest compound they offer (C5) can provide a lap time advantage of up to 0.5 seconds per lap compared to the hardest compound (C1), but will also degrade more quickly. This highlights the trade-off between performance and durability that teams must consider when choosing their tyre strategies for a race.

How Do F1 Tires Degrade?

In F1, tyres undergo a number of stages during a race, from shiny new tyres to worn-out tyres that require replacement during pit stops.

The Heat Cycle

As mentioned, Formula 1 tyres need to heat up and be sticky to have a good grip. New sets are a little slippery at first and will take around a lap or two to achieve the optimal temperature. By heating a new tyre this way, the rubber is cured and the tyre will reach its maximum temperature faster. Most drivers prepare their three racing tyres for the race during free practice sessions by putting them through heat cycles.

Tire Blistering

When the inside of the tyre is hotter than the outer rubber or tread, blistering will occur. If the air is hot enough, it will force its way out between the rubber layers, ripping chunks off the tread. A tyre’s blistering can be seen when the tread is missing patches. There is less rubber contact with the track when a tyre is blistered, so the tyre will not provide good grip.

Tire Graining

As the tread of the tyre becomes very hot, the rubber will melt, and the centrifugal forces will scatter the melted rubber. A portion of the melted rubber will adhere to the tyre tread; this is known as tyre graining. Tyres with graining resemble sandpaper and provide less grip since the grains prevent the tread from contacting the track.

Marbling

Tyre graining leaves some rubber on the race track, which accumulates off the racing line. Small rubber parts clump together to form marble-like pieces in the corners and can be seen as the darker areas on the track.

It is common for hot tyres to pick up marbles as they pass another driver, sticking to their tyres. This results in the grip disappearing.

The majority of drivers will drive through the marbling patches at the end of the race, which will add weight to their cars.

Tire Flat Spots

A flat spot occurs on the tire as the rubber is ripped away by the asphalt. The tyre will emit white smoke when it is flat-spotted as it skids or slides on the track. Tyres with flat spots are not perfectly round since part of the contact patch has been flattened. A flat spot will significantly affect a car’s handling as vibrations will occur, which can damage the car’s components.

The Environmental Impact of F1 Tire Production

The production and disposal of F1 tyres have significant environmental implications, given the large number of tyres used throughout a season and their complex composition. Pirelli, as the official tyre supplier for Formula 1, has been working to reduce the environmental impact of their tyre production and disposal processes.

One of the primary concerns is the carbon footprint associated with tyre production. According to Pirelli, the production of a single F1 tyre generates approximately 70 kg of CO2 emissions. With thousands of tyres produced each season, this can add up to a significant environmental impact. To address this issue, Pirelli has implemented measures to reduce their carbon footprint, such as using renewable energy sources in their production facilities and optimizing their manufacturing processes to minimize waste.

Another concern is the disposal of used tyres. F1 tyres are made from a complex mix of synthetic and natural rubbers, reinforced with carbon fiber and Kevlar. These materials are not easily biodegradable and can persist in the environment for long periods if not properly disposed of. To tackle this problem, Pirelli has introduced recycling initiatives, such as their “P Zero World” program, which aims to recycle used F1 tyres into new products, such as running tracks, playground surfaces, and insulation materials.

Furthermore, Pirelli has been working on developing more sustainable tyre compounds. In 2021, they introduced a new tire compound that contains a bio-based material derived from renewable sources, such as sugarcane. This bio-based material makes up around 1-2% of the total tire composition, reducing the reliance on fossil fuel-derived materials.

Despite these efforts, there is still much work to be done to reduce the environmental impact of F1 tyre production. The sport is constantly exploring new technologies and materials that can help to make tyres more sustainable, such as the use of recycled materials and the development of biodegradable compounds.

F1 Tyre Usage In 2024: The Key Numbers

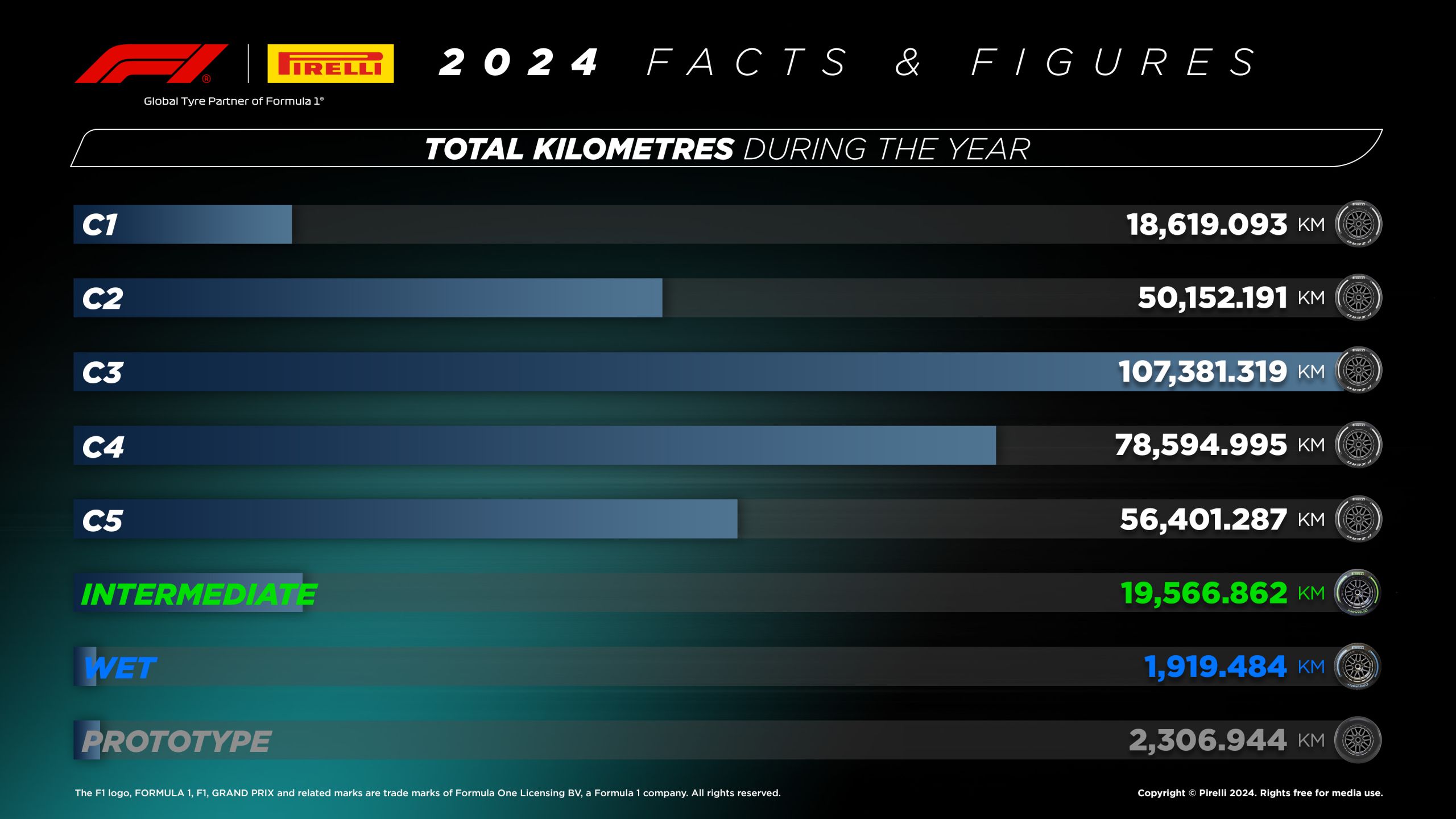

The Pirelli tyres used over the course of the 24 Grand Prix in this longest ever Formula 1 season, covered a distance that could almost see you getting from the Earth to the Moon on an imaginary road linking our planet to its only natural satellite. The tyres completed 334,942.175 kilometres, over 65.534 laps from the first free practice session in Bahrain, to the chequered flag in Abu Dhabi, which is 94% of the distance separating us from the moon’s perigee, its nearest point to earth during the 27 day orbit of our planet.

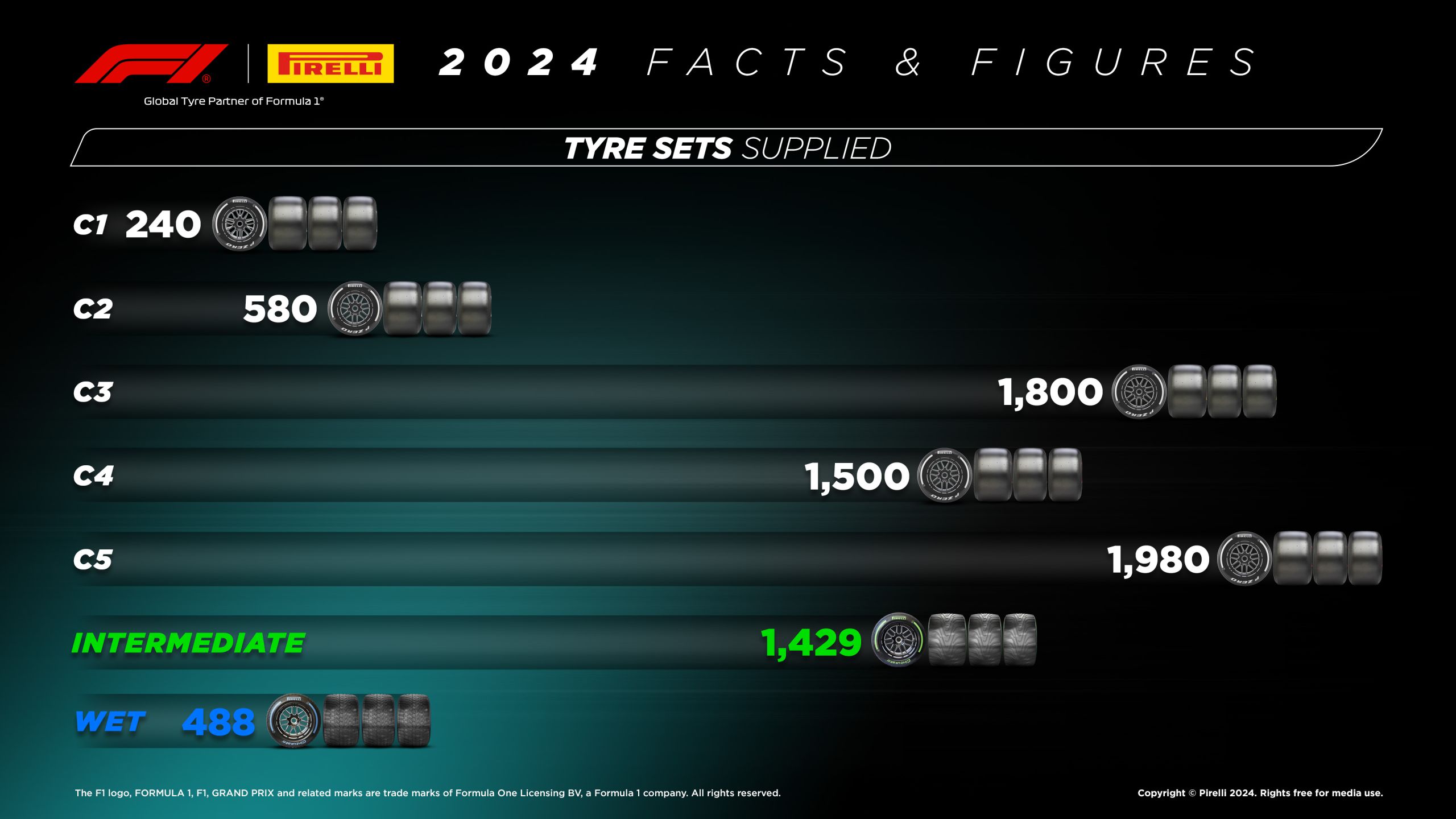

The actual distance has increased compared to 2023, thanks to the addition to the calendar of the Emilia-Romagna and Chinese Grands Prix which accounted for a further 27,016.375 kilometres. The percentage of kilometres completed on the slick tyres has remained pretty much unchanged at 93.59%, while there was an increase in use of the Cinturato Intermediate from 5.67% to 5.84% for a total of 19,566.862 km. The Cinturato Extreme Wet was used a bit less, going from 0.64% to 0.57%. Of the slicks, the lion’s share inevitably was down to the C3, as this compound was selected for every event, although in percentage terms it dropped from 36.57% to 32.06% compared to last year. Yet again, the C4 was the second most used compound (23.47%) while for third place, at 16.84% the C5 overtook the C2 (14.97%) and the C1 was once again the least used in 2024 at 5.56%. Some of these changes in the data are down to the fact that, for the races in Melbourne and Interlagos, the decision was taken to go with a softer trio of compounds than the previous year, going from C2-C3-C4 to C3-C4-C5.

Not included in the above numbers is the data relating to prototype tyres. They were used for 2,306.944 kilometres, fewer than the previous year because in 2024 they were only used for the in-competition test at Mexico City, while last year they were used in Friday free practice in three events – Barcelona, Suzuka and, as this year, Mexico City.

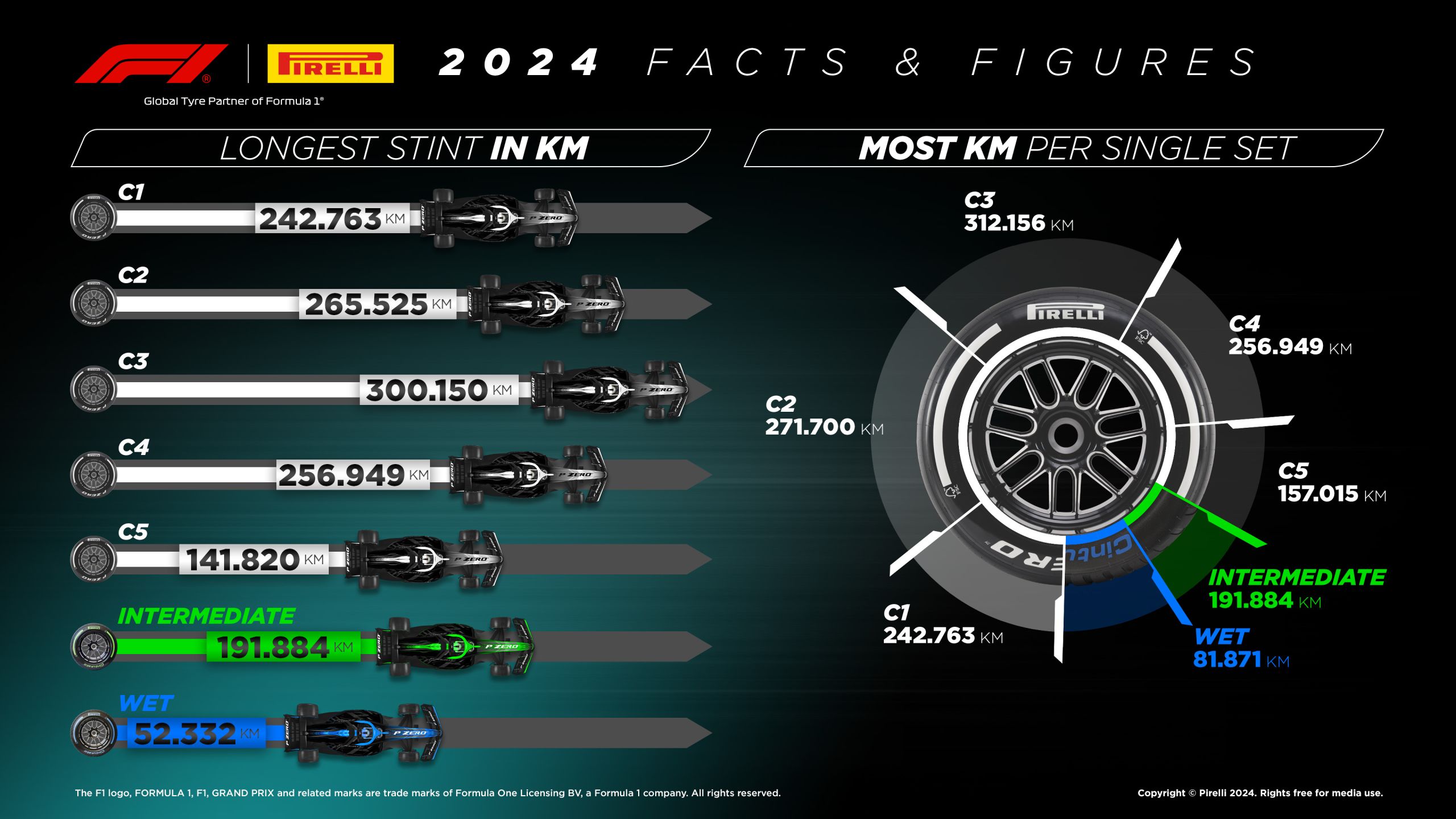

The prize for the longest stint on a single set of tyres goes to Pierre Gasly, who completed 300.150 kilometres (50 laps) in his Alpine in Baku on a set of C3s, designated as the Hard at this Grand Prix. Charles Leclerc takes the honours for the longest distance travelled on a set of C2, completing 43 laps of the Jeddah track, equivalent to 265.525 kilometres. George Russell travelled furthest on a set of C4 (256.949 km, 77 laps) in Monaco, while Nico Hulkenberg completed 242.763 km, 57 laps, at Zandvoort. Yuki Tsunoda did 28 laps of the Singapore track, equivalent to 141.820 kilometres and Racing Bulls’ Japanese driver also takes the award for the longest stint on a set of intermediates (191.844 km) in Montreal, while his team-mate for the final six races of the season, Liam Lawson, went further than anyone (81.871 km) on one set of Extreme Wets.

Pirelli supplied the teams with a total of 8,016 sets of tyres. Of these, 2,718 were never used. The extreme wet and intermediate tyres were subject to a “strip-and-fit” policy which meant that tyres fitted to rims but never used, could be stripped and refitted for use at other rounds. In 2024, this meant that around 3500 fewer tyres needed to be produced. 935 sets of slicks, equivalent to 11.66% of those produced, were fitted to rims but never saw the track. In addition, a further 948 sets (11.82%) completed between one and three laps: for the most part, these are sets used in qualifying or in flying lap simulations, but the issue of more efficient tyre usage during the race weekend remains on the table.

Of all the 2024 races, the Japanese Grand Prix saw the most tyre changes: there were 46 pit stops in Suzuka. While at the other end of the scale, there were only 19 pit stops in Jeddah. Actually, the quietest Sunday in terms of action in pit lane was in Monaco, where thanks to a red flag on the opening lap, all the drivers were able to make the obligatory change of compound during the interruption, so that after that, there were only a further seven pit stops.

If there was a prize for the hottest race of the year, at least in terms of air temperature, it would go to Interlagos, with 35.6 °C recorded during Sunday’s race. In contrast, Silverstone’s temperatures ranged from 10.9 °C, rising to 13.9 °C in the race. As for track temperatures, there were some old favourites and some newcomers compared to 2023: the prize for the hottest goes to the Hungaroring with 58.6 °C, although the race in Imola saw a surprising 52.5 °C. The coldest bit of track overall was Silverstone (12.8 °C) while during a race, Las Vegas was coldest at 16.8 °C.

F1 Tyre FAQs

Why Do F1 Teams Scrape Tyres?

Formula 1 teams come up with a lot of strategies within the regulations to improve current and future car performance. One of these is a process called tyre scraping.

A layer of gum-like substance is found on previously used tyres that have been run on, resulting from the melting of rubber as well as debris from cars driving off the track. It is vital to remove these excess rubber particles and other debris.

Tire scraping requires a tool similar to a heat gun—a tool that generates steam of very high temperature enough to melt the surface of a used tyre. This process melts a layer of the tyre, revealing what lies underneath. As a result, they get a tyre that looks almost brand new.

This process has a lot of benefits. One, it widens the tyre patch in contact with the road— providing more grip. Two, it reduces the tyre’s weight. Three, it reduces overheating which then reduces tyre degradation.

Can Formula 1 tyres be reused?

The quick answer is no. Formula 1 cars are designed as durable as possible but despite this, they are only meant to be used for one stint of Grand Prix. They cannot be reused after that.

As mentioned above, tyres go through different stages during a race: Heat cycle, blistering, graining, marbling and flat-spotting. These stages wear a tyre. Worn out tyres will affect a car’s performance during a race—lowering its ability to provide reliable gripping on the surface of the track. However, if the tyres aren’t damaged, teams are allowed to reuse them for multiple sessions.

Because of this, Formula 1 teams are allowed to change tyres as needed and when they are too worn out.

How Many Times Can Tyres In F1 Be Changed?

There are no concrete limits to how often a team can change tyres and depending on the race conditions, some teams don’t even change more than once. It varies per circuit and weather conditions. When the weather is wet, tyre changes are even trickier.

It becomes even more tricky in wet weather conditions, sometimes requiring a driver to pit and change tyres several times as the track conditions and weather conditions change. On a rainy day with a wet track, Wets and Intermediates are used.

In total, twelve sets of the Zero slick tyres may be used by each driver: six sets of soft compound, four sets of the medium compound tyre and two sets of the hard compound.

In addition, four sets of intermediates and three sets of full wets are also provided.

Furthermore, if Free Practice 1, Free Practice 2, or Qualifying is held in wet conditions, each driver will receive an extra set of intermediates. Should the Sprint Qualifying be held in the wet, a further set of intermediates is available.

What Happens To Used F1 Tires After The Race?

When the tyres are deemed unusable, teams return them to Pirelli. It may come as a surprise but the tyre company actually recycles these used tyres under their Green Technology program. They have been using this program since 2002.

The tyres are shredded and melted in their plant using a controlled process. Small rubber pellets are then formed from these shredded tyres. Tire-derived fuels are manufactured from these pellets and used by the following industries:

Electric, Utilities

Industrial Boilers

Cement Manufacturing

The Paper and Pulp Industries

Tire to Energy Facilities (such as Pirelli’s own plant)

Tire manufacturers around the globe use the same method.

How is this process beneficial to our environment? Tire-derived fuels are a renewable energy source that reduces our dependency on fossil fuels.

Formula 1 has been looking for ways to become environment friendly in the future, with the sanctioning body announcing its plans to create 100% sustainable fuel for its next-generation engines. According to them, they intend to create fuel that can produce the same level of performance while emitting net zero carbon dioxide.

With this big step taken by Formula 1, it shouldn’t be a surprise that their tyre provider is somewhat sharing the same vision as them.

From F1 news to tech, history to opinions, F1 Chronicle has a free Substack. To deliver the stories you want straight to your inbox, click here.

For more F1 news and videos, follow us on Microsoft Start.

New to Formula 1? Check out our Glossary of F1 Terms, and our Beginners Guide to Formula 1 to fast-track your F1 knowledge.